We provide classroom training programs and practical implementation of quality core tools such as EPQP, FMEA, SPC, MSA and PPAP.

Currently we focus on Total Productive Maintenance (TPM) on shop floor, value stream mapping and shop floor management. Our easy to understand training sessions from industry experts will make difference in your company.

We also help in IATF Documentation and Audits

IATF 16949:2016 Customer Specific Reference Manuals

As a Customer Specific requirement and supplement to IATF 16949:2016 there are a variety of guideline manuals that define customer requirements and the methods and practices to be used and incorporated into the Management System activities, referred to as “Core Tools”.

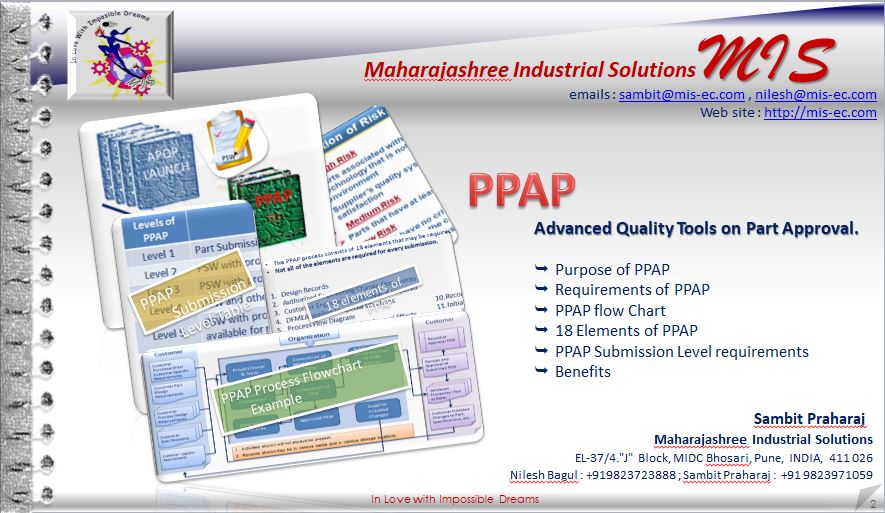

- Production Part Approval Process (PPAP)

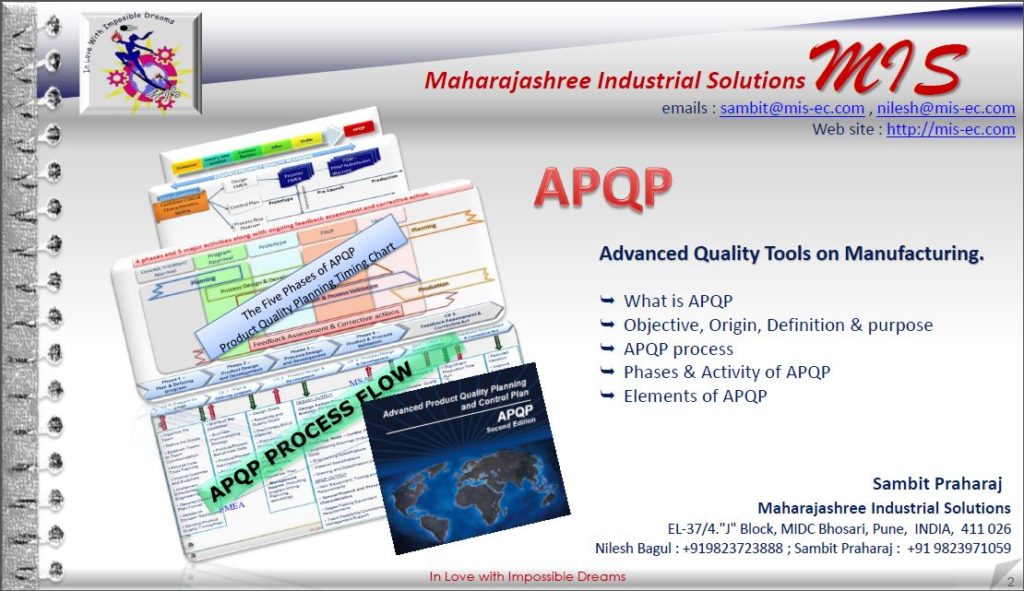

- Advanced Product Quality Planning and Control Plan (APQP / CP)

- Failure Mode and Effects Analysis (FMEA)

- Measurement System Analysis (MSA)

- Fundamental Statistical Process Control (SPC)

This module is intended to provide training and awareness of the “Core Tools” manuals and how they are utilized during the audit process along with a general overview of their intent and utilization in the planning and manufacturing process.

Building Quality

“Zero” Defect

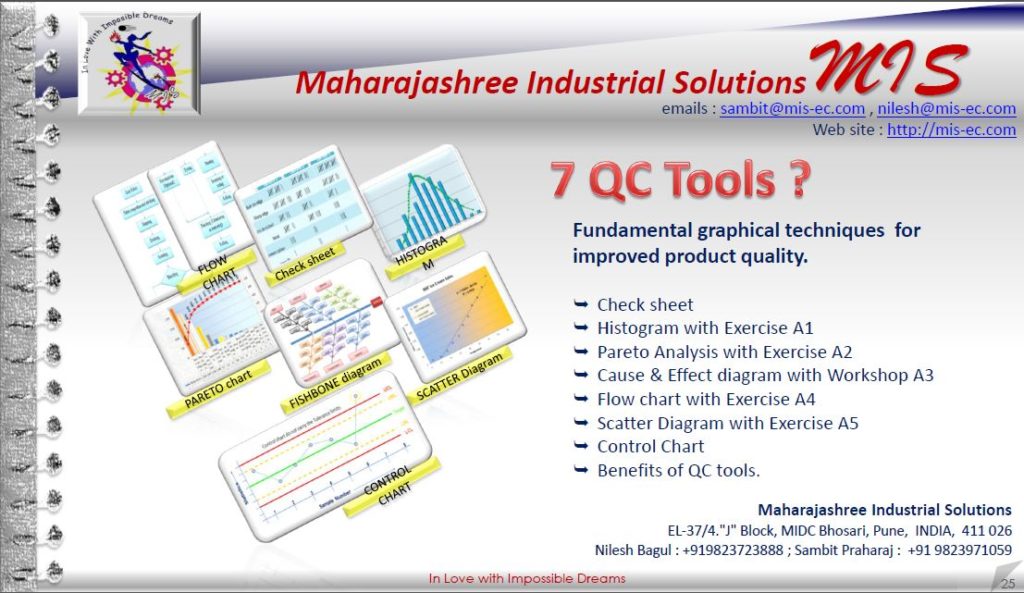

“7” QC Tools

APQP

PPAP

PFMEA & Control Plan

SPC & Control Chart

MSA and SPC

Frequently Asked Questions (FAQs)

Why APQP?

Proactive feedback & corrective action planning, Direct organisation resources to satisfy the customer and promote a quality product on time at the lowest price

Who needs to know?

Employees at all level need to know about this tool.

Who needs to be Expert?

Quality engineers, Process engineers and Development engineers.

Who needs to follow?

All including Operators.

What is the duration of overview training?

4.5 days (30 hrs)

How to implement?

Interactive coaching in developing and implementing Core Tools within the organization. Additional visit.

What is required from the organization ?

Commitment to do. Rest is with us.